Ceramic Filters

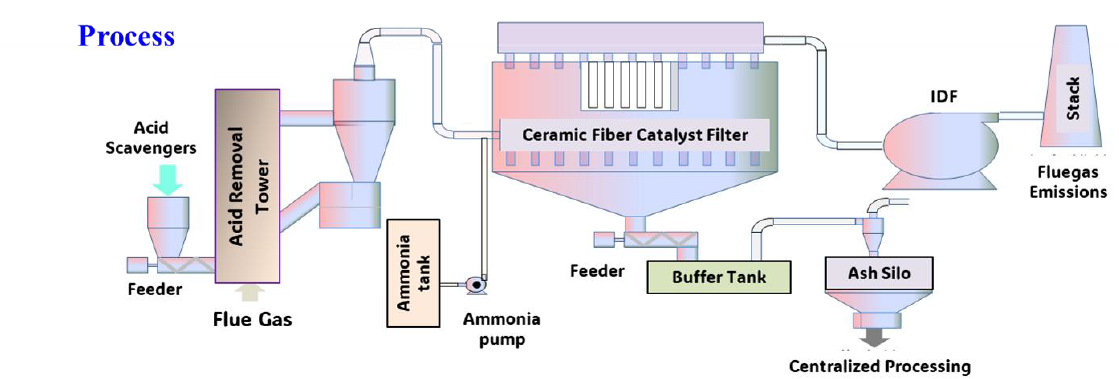

ZAIN offers efficient and environmentally responsible high-temperature filtration solutions using advanced ceramic filter technology capable of operating at temperatures up to 1,000°C—far exceeding the limits of conventional fabric. Our catalytic ceramic filters simultaneously remove particulate, SOx, and NOx in a single step, reducing equipment footprint, cutting both capital and operating costs, and enabling materials recovery from exhaust.

Efficient & Environmentally Responsible Filtration

High-temperature dust removal from particulate-laden exhaust gases offers compelling advantages both economically and ecologically. Unlike synthetic fabric filters, which are limited to around 260 °C, ceramic filter elements allow filtration up to 1000 °C—eliminating the need for costly gas cooling.

Today, hot-gas filtration extends beyond air pollution control. By reclaiming valuable particulates from exhaust streams and reintegrating them into production processes, operators improve plant efficiency while conserving raw materials. Additionally, high-temperature dust removal enables effective heat recovery and even power generation.

The 3-in-1 Advantage: Clean Air, Fewer Interfaces

Catalytically coated hot-gas filter cartridges provide a multifunctional solution for complex gas treatment. These filters tackle three pollutants simultaneously—dust (DeDust), sulfur compounds (DeSOx), and nitrogen oxides (DeNOx)—within a single step. The benefits include:

- Fewer interfaces

- Smaller plant footprint

- Significant CAPEX and OPEX savings

Ceramic Filters: A Smarter Investment

Textile filters serve smaller installations adequately, but ceramic filters outperform across broader temperature ranges—making them ideal for medium to large-scale systems. With ceramic filter cartridges, process temperatures up to 1000 °C are easily accommodated without altering downstream filtration stages.

Temperature ranges:

- Non-catalytic : 250–1,000 °C

- Catalytic-coated : 250–420 °C

Ceramic Fiber Filter

- Filter Bag Replacement: Same Use as Traditional Collectors.

- High Temperature & Corrosion Resistance: Superior Heat & Corrosion Resistance.

- Longer Lifespan: Lasts Significantly Longer than Standard Filter Bags.

Ceramic Fiber Filter

- Low-Temp Advantage: DeNOx Works at 170-380°C.

- Smaller Gas Volume, Footprint, and Cost.

- Longer Catalyst Life with Fiber Protection.

- Supports DeSOx: Less Ammonium Salt, Longer Catalyst Use.

Easy Installation | Modular & Scalable Lengths (1–4 Meters)

Adaptation to evolving system requirements is straightforward. By increasing filter surface area with longer cartridges—up to 4 meters—existing setups can be upgraded with minimal structural changes (provided tank height allows). If ceiling constraints exist, the patented Screw-and-Glue® system enables on-site assembly from 1-meter segments, ensuring flexibility and cost-effective installation.

Compared with SCR+bag filter, CCF as following advantages:

- Low Energy Use: effective DeNOx and dust removal at 170–350 °C, reducing costs.

- Low-Temp Advantage: less gas expansion, lower equipment cost, competitive edge.

- Extended Catalyst Life: fiber filters protect and prolong catalyst use.

- Acid Removal Combo: reduces ammonium salts and protects filters with dry powder.

- Dual-Function Catalyst: removes NOx and dioxins, prevents dioxin reformation (de novo).

Products

Ceramic Fiber Filter

Maximum Operating Temperature

900°C

Normal Operating Temperature

Below 700°C

Minimum Operating Temperature

Acid Dew Point +20°C

Ceramic Fiber Catalyst Filter

Maximum Denitrification Temperature

380°C

Denitrification Operating Temperature

170~380°C

Minimum Denitrification Temperature

ABS Dew Point

Dioxin

180~250°C

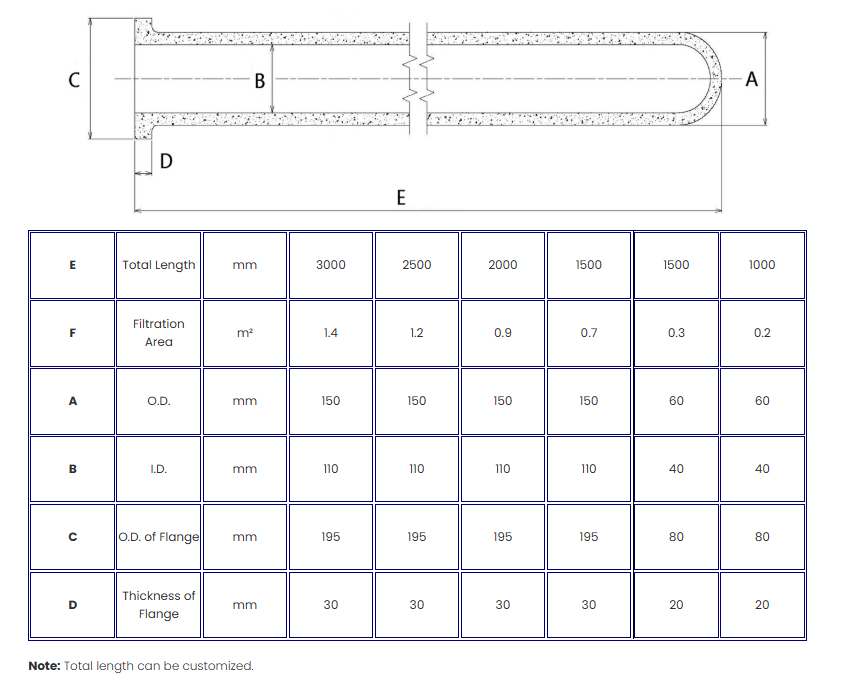

Filter Dimensions

E

F

A

B

C

D

Total Length

Filtration Area

O.D.

I.D.

O.D. of Flange

Thickness of Flange

mm

m²

mm

mm

mm

mm

3000

1.4

150

110

195

30

2500

1.2

150

110

195

30

2000

0.9

150

110

195

30

1500

0.7

150

110

195

30

1500

0.3

60

40

80

20

1000

0.2

60

40

80

20

Note: Total length can be customized.

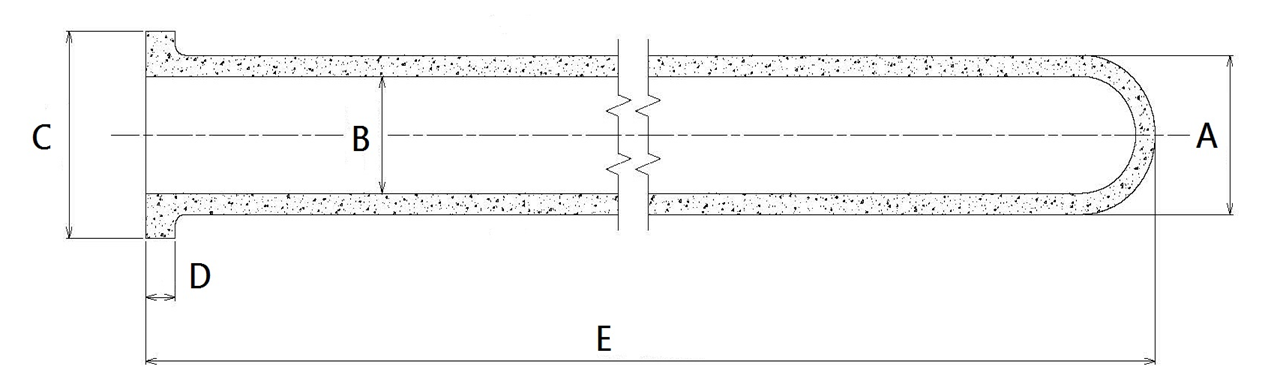

Catalytic Filter Dimensions

Click to Enlarge

WE REPRESENT

Clean World Technology Corp.

Clean World Technology Corp. is an international enterprise that brings together the global forces of environmental protection technology. It was jointly founded by strategic shareholders from Hong Kong, Taiwan, the United States, the United Kingdom, and other places.