Glass-Lined Stirred Tanks & Reactors

ZAIN represents Thaletec's comprehensive range of glass-lined stirred tanks and reactors, engineered to meet the rigorous demands of chemical, pharmaceutical, and food processing industries. These vessels combine the structural strength of steel with the superior corrosion resistance of a glass lining, ensuring durability and product purity in various applications.

Innovative Glass-Lined Reactor Technologies

Thaletec is a global leader in glass-lining technology, delivering advanced equipment and solutions for the chemical, pharmaceutical, energy, and environmental industries. With a focus on innovation, precision, and long-term reliability, Thaletec provides customized products that optimize performance, safety, and efficiency throughout every stage of your process.

Discover Thaletec’s latest innovations in:

- Glass-lining technology

- Mixing and agitation systems

- CIP and GMP process solutions

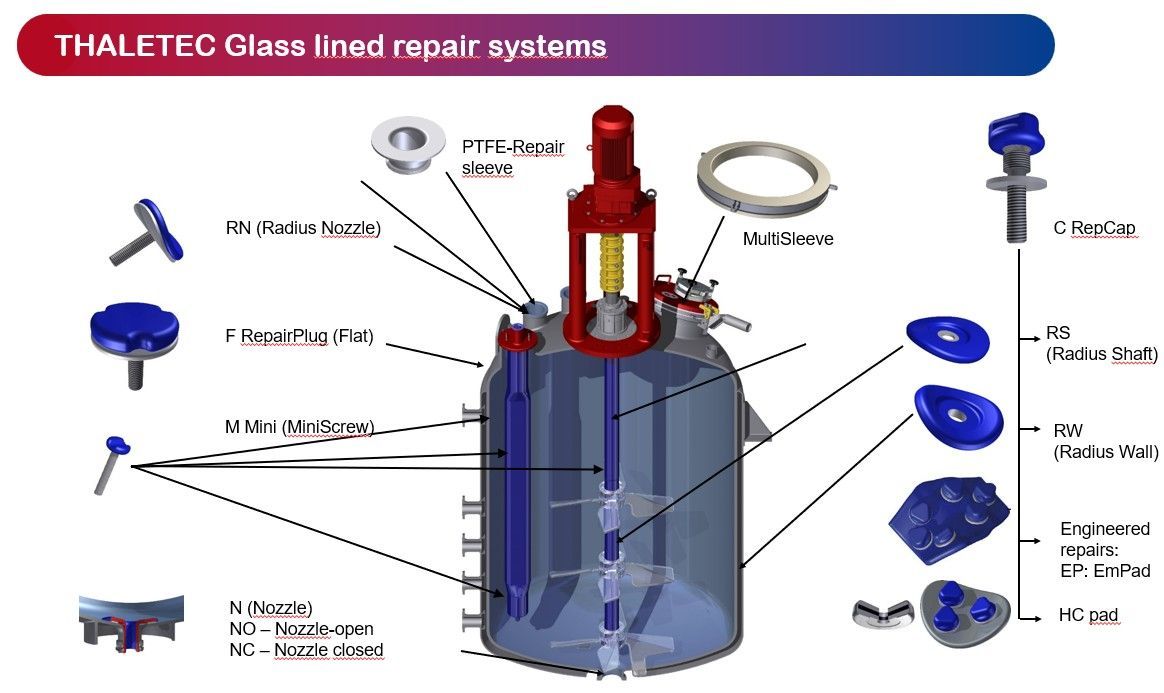

- Repair and reglassing services

Interested in Learning More?

Download Thaletec’s complete Solutions Overview and explore how our expertise can help improve the performance, safety, and efficiency of your operations.

What Are Glass-Lined Stirred Tanks and Reactors?

Glass-lined stirred tanks and reactors are industrial vessels featuring a steel shell internally coated with a durable glass layer. This fusion offers a non-reactive, smooth surface ideal for processes requiring high purity and resistance to corrosive substances. The integration of stirring mechanisms facilitates uniform mixing, essential for consistent product quality.

Key Features and Advantages

- Corrosion Resistance: The glass lining provides exceptional resistance to acids, alkalis, and solvents, extending the vessel's lifespan and maintaining product integrity.

- Chemical Inertness: The inert nature of glass prevents unwanted chemical reactions between the vessel and its contents, ensuring process stability.

- Product Purity: The non-porous, smooth glass surface minimizes contamination risks, crucial for pharmaceutical and food-grade applications.

- Ease of Cleaning: The anti-stick properties of glass facilitate straightforward cleaning and sterilization, reducing downtime between batches.

- Thermal and Pressure Tolerance: Designed to withstand high temperatures and pressures, these vessels are suitable for a wide range of processing conditions.

- Process Visibility: Certain models feature glass components that allow operators to monitor reactions in real-time, enhancing process control.

- Versatility: Applicable in various processes such as polymerization, hydrogenation, crystallization, and fermentation, accommodating diverse industry needs.

Applications

Glass-lined stirred tanks and reactors are utilized in numerous industries due to their robust design and versatility.

- Chemical Manufacturing: Ideal for handling aggressive chemicals and reactions requiring precise control.

- Pharmaceutical Production: Ensures high purity and compliance with stringent regulatory standards.

- Food and Beverage Processing: Maintains hygiene and prevents contamination in sensitive food-grade applications.

- Biotechnology: Supports processes like fermentation and cell culture with consistent performance.

Considerations When Selecting Glass-Lined Equipment

When choosing the appropriate glass-lined stirred tank or reactor, consider the following:

- Process Requirements: Evaluate the chemical compatibility, temperature, and pressure conditions of your application.

- Regulatory Compliance: Ensure the equipment meets industry-specific standards and certifications.

- Maintenance and Inspection: Assess the ease of cleaning, maintenance needs, and accessibility for inspections.

- Manufacturer Support: Opt for suppliers that offer comprehensive support, including installation, maintenance, and spare parts availability.

ZAIN is committed to providing high-quality glass-lined stirred tanks and reactors that meet the diverse needs of our clients. Our expertise ensures that you receive equipment tailored to your specific process requirements, backed by reliable support and service.

For more information or to discuss your project needs, please contact us.