Glass Inspection & Repair Services for Glass‑Lined Reactors

ZAIN—Your Consultant for Glass-Lined Reactor Solutions

Partnered With THALETEC, Our Service Is Available for You Anytime

Is your glass-lined reactor operating safely and efficiently? ZAIN provides professional inspection and repair services for glass-lined reactors, tanks, and accessories to businesses in the USA and Canada. Our trained personnel, located out of North Carolina, use industry-standard methods—spark testing, thickness measurement, visual inspection, and, if needed, full reglass restoration—to verify liner integrity and extend equipment life. Our schedule is flexible to meet your requirements. This allows us to ensure that your production equipment can be quickly and reliably serviced and repaired—we deliver detailed diagnostics and execute repair or reglass solutions on-site or in our partner facilities, ensuring compliance and operational reliability.

Thaletec Has Innovative Solutions to Address Common Challenges Using Glass-Lined Reactors

- Electrostatic Charge Buildup

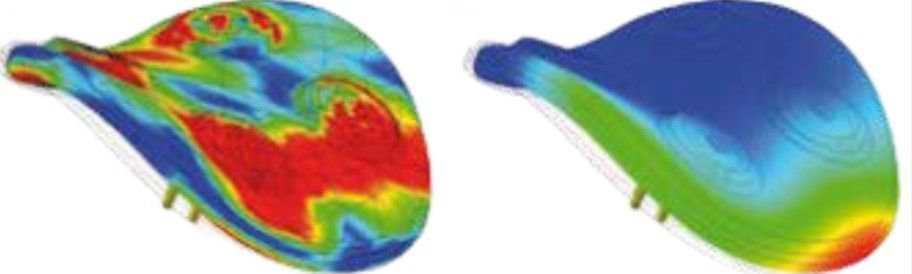

- Thermal (Heat Transfer) Limitations

- Mixing/Baffling

- Paint Chipping from Manway Cover

- Powder Addition into the Reactants (Sparging)

- Bottom Outlet Nozzle

- Polymers Sticking to Glass (Imperfections)

- Diaphragm Ring: Buildup of Deposit

- Glass Damage and Repair with Glass (Not Tantalum—Why?)

Contact us or read more below about our services and aftermarket parts.

What We Offer

Glass-Steel Testing

To ensure the safe and reliable operation of glass-lined equipment, periodic testing of the glass linings is essential. Common test procedures include:

- High Voltage Test

- Visual Inspection

- Layer Thickness Measurement

For a fast and non-intrusive assessment, the THALETEC Glass Detective provides a quick and efficient testing solution without the need to enter the equipment.

THALETEC Glass Detective Portable

The THALETEC Glass Detective Portable is a user-friendly, mobile device designed to test glass-lined and plastic-coated surfaces in process equipment such as reactors, tanks, and columns. It operates on the principle of electrical capacitor analysis, measuring the integrity of the glass-lined surface through the sensor electrodes for fast and reliable results.

Advantages of THALETEC Glass Detective

- Compact and easy-to-transport device.

- Easier and faster glass inspection.

- Tantalum repairs do not cause any false alarms.

- In operation at call, even without practice and reading a lengthy manual.

- No operator controls, as the test operation runs automatically.

- Operation without operating errors.

- High accuracy of damage detection.

- Can also be used to check tanks and pipelines with other non-conductive linings such as PTFE.

How It Works

The conductivity between the process media and the platinum or gold electrodes is carefully measured. If any damage occurs on the glass lining, the system immediately detects signs of corrosive attack. The electronic device then analyzes the issue and presents clear results.

Glass-Lining Damaged? What’s Next?

If test results show any damage, reach out to our service team. Our experts are ready to provide reliable inspection, repair, and restoration to ensure your equipment continues to perform at its best.

Glass-Steel Repairs

THALETEC EmRep is an innovative repair system designed specifically for glass-lined tanks and equipment. Using specially developed glass-lined components, this system allows for the permanent repair of defects ranging from as small as 2 mm up to 300 mm. Even minor damages on critical parts—such as turbines, shafts, or baffles—can be effectively restored, ensuring extended equipment life and reliable performance.

LocaRep: Fast and Cost-Effective Glass-Lined Repairs

LocaRep offers a quick and economical solution for minor glass-lined equipment damage. With the THALETEC MiniScrew system, small defects up to 8 mm in diameter can be safely and permanently repaired, ensuring reliable performance without costly downtime.

RepCap: Reliable Repairs for Larger Glass-Lined Defects

RepCap provides a simple and efficient solution for safely and permanently repairing small damages up to 14 mm in diameter on glass-lined components. In addition to addressing localized defects, the RepCap system can also serve as a secure fastener for extensive repairs using glass-lined plates, ensuring long-lasting performance and equipment reliability.

RepairPads: Versatile Solutions for Larger Glass-Lined Repairs

RepairPads (RW, RS, and RN) are designed to safely cover damages up to 300 mm in diameter and can be adapted for flat, concave, or convex surfaces. For geometrically complex areas, THALETEC provides customized RepairPads, engineered with advanced 3D software to ensure a precise fit and long-lasting protection for your glass-lined equipment.

EmPads: Durable Glass-Lined Solutions for Industrial Equipment Protection

EmPads are manufactured using an advanced, innovative process and are subsequently glass-lined for superior durability and chemical resistance. Ideal for industrial applications, EmPads provide reliable performance and long-lasting protection for your equipment.

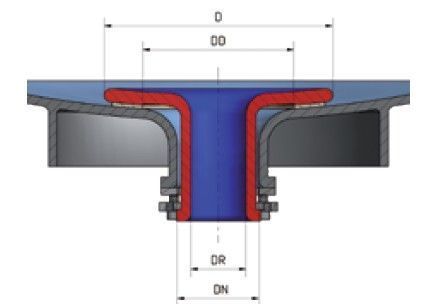

THALETEC RepSet: Reliable Repairs for Bottom Outlet Connections

The THALETEC RepSet is designed to repair larger damages on bottom outlet connections. Standard inserts are available for bottom outlet sizes DN 100 and DN 150, ensuring a precise and reliable fit.

Are you interested in one of these services or want to learn more? Contact us today!

Spare Parts

THALETEC provides a comprehensive range of spare parts for glass-lined tanks, columns, agitators, heat exchangers, pressure filters, and specialized equipment. Most spare parts conform to standard specifications (DIN, EN, etc.) and are readily available from our warehouse, ensuring quick and reliable replacement solutions.

Parts We Offer

- Caps

- Glass-Lined Flanges

- Clamps

- Valves

- Baffles

- Mechanical Seals

- Protection Rings

- Gaskets

- Backing Flanges

- Impellers

- Sight Glasses

…and Much More! If you don’t see the part you need, please contact us. We’ll be happy to help you find the exact spare part for your equipment.

Frequently Asked Questions

Who is ZAIN Industrial?

ZAIN Industrial is a leading expert in industrial mixing solutions. We specialize in providing consulting services, Mixing tanks and reactors as well as Field Services.

What does glass lining inspection involve?

We perform visual inspections to identify cracks or chips, spark (holiday) testing to detect micro-defects, and thickness measurements to check for wear or erosion. We compile all results in a maintenance log for long-term tracking and compliance.

How often should inspections be conducted?

We recommend annual inspections as part of your preventive maintenance program. Some high-use or corrosive-process systems may require check-ins every 6 months to avoid unexpected failures.

What repair methods do you offer?

Minor defects can often be fixed with on-site patch plugs, sleeves, or PTFE repairs. For severe wear or damage, we offer full reglassing services that restore vessels to like-new quality while often reducing cost compared to full replacement.

Can seals and agitator components be checked during inspection?

Yes. Our inspections cover agitator shafts, drive seals, baffles, nozzle connections, and gaskets. We'll identify worn or corroded elements and recommend replacements or adjustments to avoid further liner damage .

Is your inspection service compliant with safety regulations?

All services comply with OSHA confined-space entry, lockout/tagout, and process safety protocols. We document every step to support regulatory requirements such as FDA or cGMP audits.

What is the timeline for inspection and repair?

Standard on-site inspections with minor on-site repairs can be completed within a day or two. If reglassing is needed, total turnaround is typically several weeks, significantly faster than sourcing new equipment .

Can a vessel be refurbished rather than replaced?

Yes—if the steel substrate is in sound condition, reglassing is often the most cost-effective solution. It restores full functionality at around 60‑70% of the cost of new equipment and preserves existing infrastructure .

When is a reactor not a candidate for repair?

If the steel shell has advanced corrosion, structural damage, or if capacity needs changes, replacement may be preferable. Our inspection report includes a technical recommendation to guide decision-making.

Visit Us!