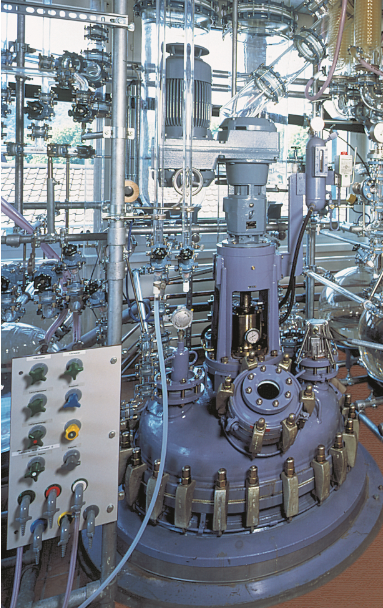

Expert Consulting for Custom Glass-Lined Reactors

ZAIN—Your Consultant for

Custom Glass-Lined Reactors

We specialize in helping you specify, evaluate, and optimize Custom Glass-Lined Reactors tailored to corrosive, high-purity processing—without pushing product or sales.

Why Custom Glass-Lined Reactors Matter

- Tailored Corrosion Protection — Custom reactors can be lined with specialized glass coatings or additional layers to withstand highly corrosive media unique to your process, ensuring extended equipment life.

- Process-Matched Geometry & Ports — Manufacturers can customize nozzle configurations, inlet/outlet placements, and vessel geometry—including unique H/D ratios and side-wall ports—for seamless integration into your system layout.

- Enhanced Safety Features — Options such as pressure relief valves, temperature sensors, and automation support can be incorporated to meet safety, monitoring, and control requirements specific to your process.

- Precise Thermal Control — Custom heating or cooling jackets—using steam, water, or thermal fluids—can be designed to regulate reaction temperatures accurately and efficiently.

- Optimized Long-Term Value — Although custom reactors may have higher initial costs, they deliver improved operational efficiency, reduced downtime, and process-specific performance benefits that reduce total cost of ownership over time.

Our Consulting Services

Needs Assessment

We begin by assessing your unique process requirements—such as chemical compatibility, temperature and pressure conditions, mixing dynamics, and geometry constraints—and tailor glass-lined reactor configurations to precisely fit.

Specification Development

We help you craft detailed Request for Quotation (RFQ) packages with custom specifications—such as H/D ratios, nozzle layouts, jackets, and specialized lining options—ensuring clarity and alignment with your technical needs.

Vendor Review & Bid Evaluation

We objectively evaluate vendor proposals and customization options, guiding you toward suppliers who can deliver performance, reliability, and long-term value.

Performance Analysis

We review your custom reactor design and operation, recommending enhancements for thermal control, agitation efficiency, and cleaning processes to boost productivity and longevity.

Technical Training & Knowledge Transfer

We provide hands-on training for your team on cleaning (CIP/SIP), reactor maintenance, and best practices in operating your custom glass-lined equipment.

Who We Work With

Chemical processors working with aggressive chemistries.

Pharmaceutical and biotech plants needing regulatory-grade purity.

Food and biotech sectors leveraging glass-lined assets.

OEMs and engineering firms that design or integrate reactors and vessels.

How ZAIN Adds Value

1

Unbiased guidance—we don’t sell equipment, only provide expert analysis.

2

Technical authority—we ensure mixing and vessel specs are optimized for your process.

3

Cost savings—we negotiate bids to save on capital, operating, and maintenance expenses.

4

Experience-driven—industry knowledge drawn from global glass-lined reactor integrations.

Why Choose ZAIN for Custom Glass-Lined Reactors Consulting?

Choosing ZAIN for custom glass-lined reactors consulting means partnering with experts who understand the unique challenges of handling corrosive chemicals and high-purity processes. With years of experience, ZAIN helps optimize the performance, safety, and longevity of your custom glass-lined reactors to ensure maximum efficiency.

Our consulting services cover everything from selecting the right custom glass-lined reactors to vendor evaluation, bid assessment, and process optimization. We also provide hands-on training so your team can confidently operate and maintain the custom glass-lined reactors , minimizing downtime and operational risks.

By working with ZAIN, you get a partner dedicated to enhancing productivity and reliability across your operations, ensuring that every piece of custom glass-lined reactors performs at its best.

Frequently Asked Questions

Discover everything you need to know about ZAIN Industries—from our innovative industrial mixing solutions and expert consulting services to practical answers on process optimization and how to contact our team.

Who is ZAIN Industrial?

ZAIN Industrial is a leading expert in industrial mixing solutions. We specialize in providing consulting services, Mixing tanks and reactors as well as Field Services.

What services do you offer?

We offer optimum mixing equipment design and selection from innovative suppliers. Onsite glass repair and preventative maintenance. Optimization of your existing mixing processes.

Which industries do you serve?

Our expertise spans a wide range of industries, including specialty chemicals, pharmaceuticals, water and wastewater, paints and adhesives. We tailor our solutions to meet the unique needs of each industry.

How can I access your mixing guides?

What makes your mixing solutions unique?

At ZAIN Industrial, we combine decades of industry experience with a commitment to transparency and innovation. Our unbiased approach ensures that you receive the best recommendations, helping you save time and money while optimizing your process.

How do you ensure the quality of your consulting services?

We work as part of your team, thoroughly reviewing process requirements and equipment specifications. Our expert consultants conduct third-party reviews to guarantee that every recommendation meets industry standards and delivers optimal performance.

How can I request a consultation or more information?

For personalized advice we will assist you in writing the request for quote by understanding your process needs. Visit our Contact page. Our team is always ready to assist you with your mixing technology needs.

Where can I learn more about your company?

Visit our About page to learn more about ZAIN Industrial. We invite you to explore our website and discover how we can help improve your process efficiency.