Mixing Efficiency Review Services

ZAIN offers expert mixing efficiency audits and optimization reviews to help industry professionals reduce cycle time, energy use, and production costs. Our data-driven assessments leverage tracer testing, power consumption analysis, hydrodynamics modeling, and operational audits to maximize mixing performance.

Why Conduct a Mixing Efficiency Audit?

Evaluating your mixing system helps identify bottlenecks, dead zones, and inefficiencies that affect product quality and throughput. A well-designed mixer can reduce power usage, shorten mixing time, and improve homogeneity—factors essential to reducing cycle time and waste. Our audits normalize performance metrics against industry best practices to benchmark your operations.

Tracer Testing & Residence Time Analysis

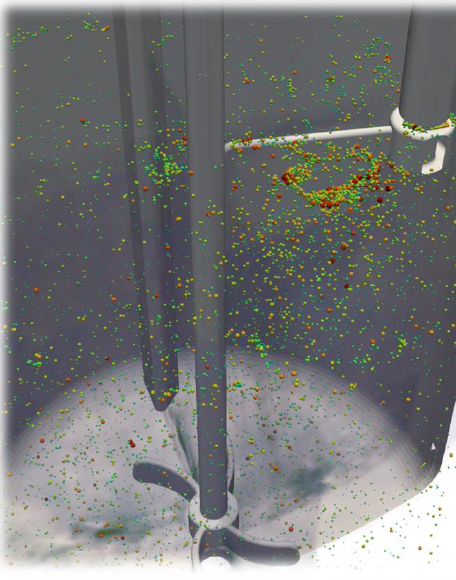

We apply tracer-study methods—such as Rhodamine dye or lithium chloride—to map flow patterns and residence time distribution inside your mixing tanks or vessels. This technique pinpoints short-circuiting or dead zones and helps calibrate mixing intensity to achieve consistent. Data from these tests inform recommendations for impeller positioning, feed entry, and baffle layout optimization.

Power & Impeller Geometry Review

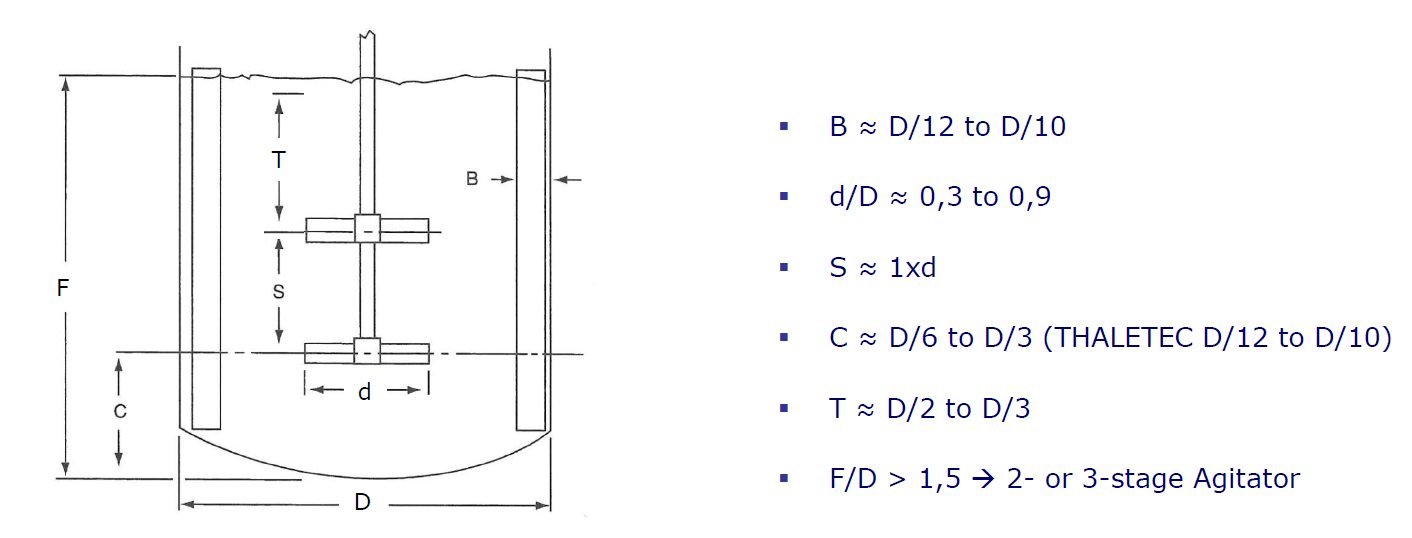

Our engineers analyze impeller design, blade shape, and tank geometry to calculate power consumption, mixing time, and circulation efficiency. Studies show optimized impeller geometry can lower power costs while improving process throughput. We examine existing setups and recommend blade upgrades, RPM adjustments, or geometry changes to reduce energy per unit volume and enhance mixing efficacy.

Computational Fluid Dynamics (CFD) & Simulation

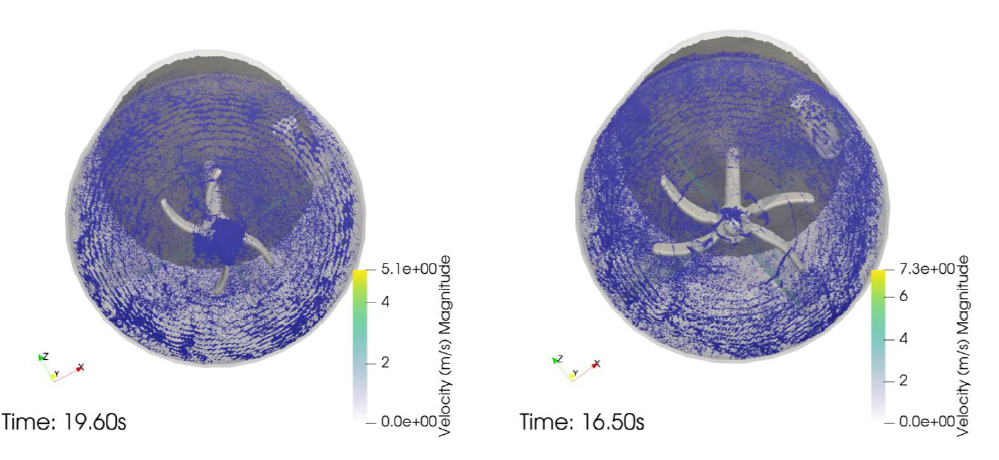

We utilize

CFD modeling to visualize flow dynamics and tracer dispersion for complex or high-viscosity applications. CFD lets us simulate design changes—like adjusting impeller size or injection points—to improve efficiency before field trials. This virtual tuning reduces risk and accelerates optimization.

Operational Optimization Recommendations

Our final audit includes customized action plans such as:

- One‑pot or semi‑continuous mixing strategies to reduce contamination and batch-to-batch variability.

- Ideal batch size adjustments to improve turnaround and throughput

- Equipment upgrades (e.g., static mixer retrofits or agitator redesigns) for consistent quality and efficiency

We provide step-by-step implementation roadmaps aligned with your production schedule and budget.

Benefits of Mixing Efficiency Reviews

01

Shorter mixing cycles and increased throughput

02

Lower energy costs and enhanced sustainability

03

Improved mixing uniformity and product consistency

04

Minimized downtime and optimized maintenance schedules

05

Data-backed performance improvements and ROI decisions

These reviews help align your mixing operations with technology best practices and operational benchmarks

Frequently Asked Questions

Who is ZAIN Industrial?

ZAIN Industrial is a leading expert in industrial mixing solutions. We specialize in providing consulting services, Mixing tanks and reactors as well as Field Services.

What mixer types can you review?

We support pitched-blade impellers, high-shear agitators, static mixer inserts, ribbon blenders, and more.

How long does the efficiency audit take?

A full audit typically spans 1–5 days depending on process complexity.

Is on-site testing required?

Yes, tracer and power testing must be done on-site; CFD simulations can be run remotely.

Can I retrofit a static mixer into an existing tank?

In many cases yes—Swiss-designed static mixers can significantly enhance inline mixing without vessel modification.

Will this reduce energy consumption?

Yes; optimized impeller geometry and RPM settings often cut power usage by 10–30%.

Visit Us!