What Are Static Mixers? History and How They Work

Understanding Static Mixers and Their Role in Modern Industry

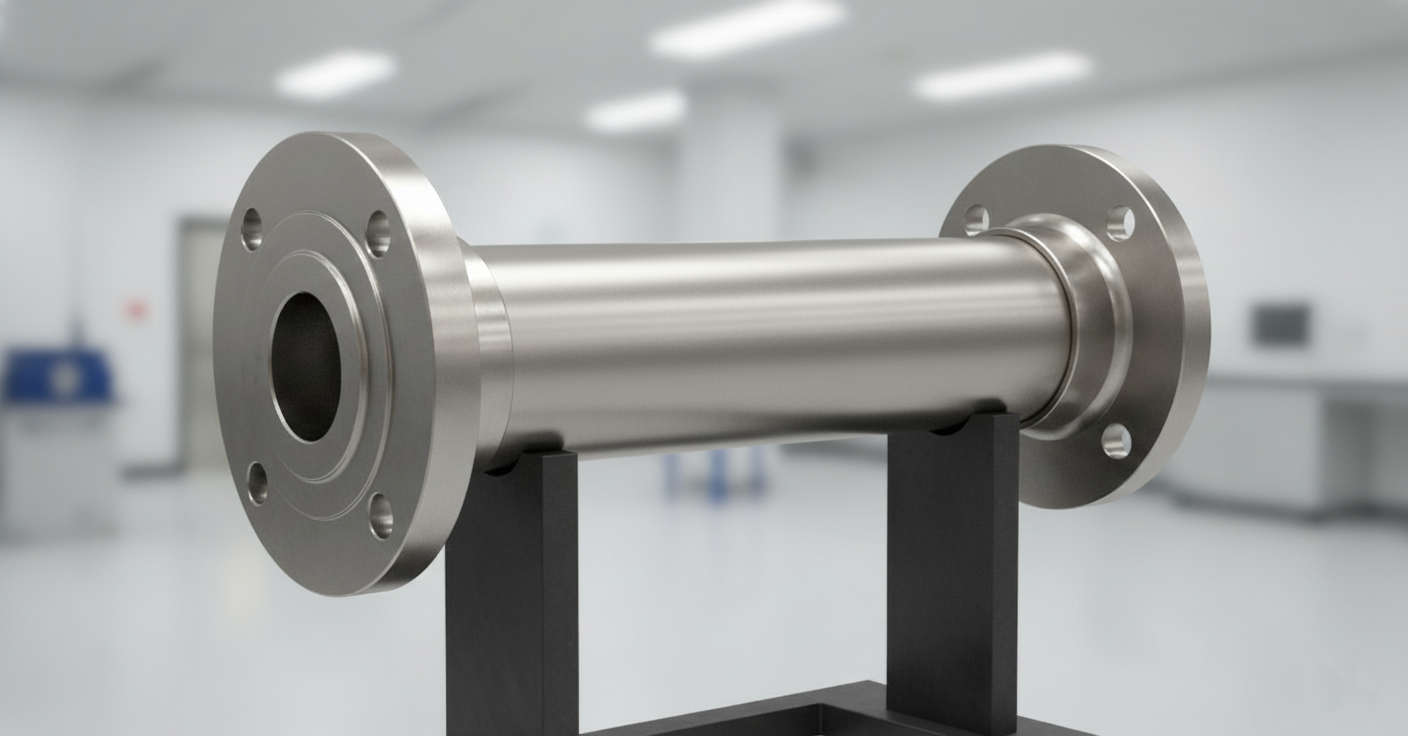

Static mixers are essential components in many industrial processes, providing efficient, consistent blending without the need for moving parts. Unlike traditional mechanical mixers, static mixers rely on fixed internal elements that create flow patterns to mix liquids, gases, or even slurries as they pass through. They are widely used in industries such as chemical processing, water treatment, food and beverage, and pharmaceuticals—where reliability, precision, and low maintenance are critical.

This article explores the history of static mixers, how they function, and why they remain one of the most cost-effective and energy-efficient mixing solutions available today.

The Origin and Evolution of Static Mixers

The concept of static mixing dates back to the early 1960s, when engineers sought a method to mix fluids efficiently without using mechanical agitation. The first commercially viable static mixer was introduced by Kenics Corporation, which patented a helical mixing element design that remains the foundation for many mixers used today.

Over the decades, innovations in materials, design geometry, and computational modeling have advanced the technology significantly. Modern static mixers are now made from stainless steel, plastics, or specialty alloys and can be customized for high-pressure, corrosive, or sanitary environments.

More Information:

- The spiral static mixer was developed by Dr. S. J. Chen, PhD, Chemical Engineering, who wrote a series of articles called "KTEK" back in 1972.

- The static mixer was patented under US Patent 3286992.

- The word "static mixer" was a registered trademarkof Kenics Corporation, North Andover, MA.

How Static Mixers Work: The Science of Flow and Motion

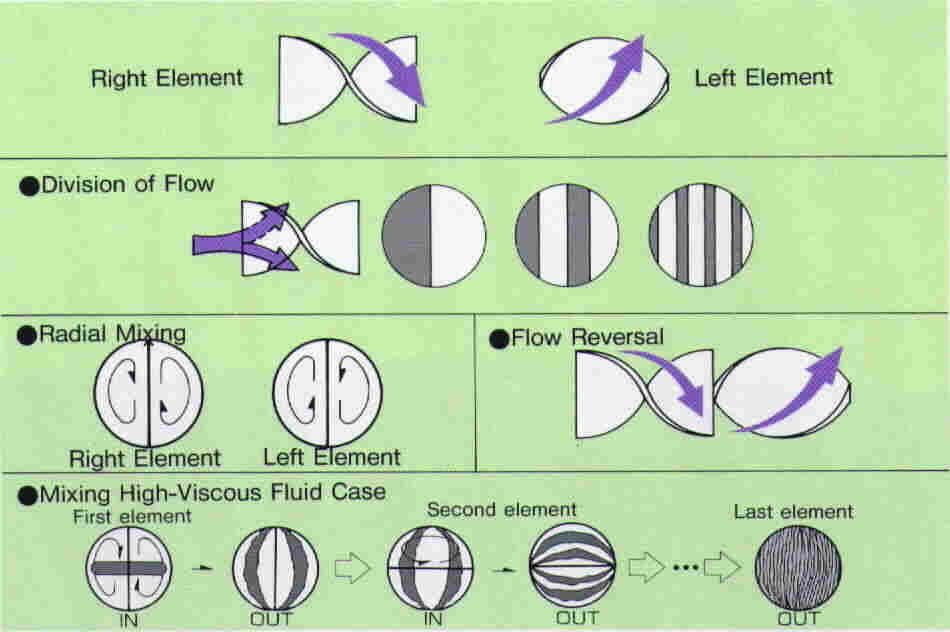

At their core, static mixers operate by dividing and recombining fluid streams as they flow through stationary elements. These elements, often shaped like twisted ribbons or intersecting blades, create turbulence and cross-flow that thoroughly blend materials.

For example, in a Kenics-type static mixer, each element is rotated 90° relative to the previous one. This sequence generates a controlled swirling motion that ensures complete mixing even in laminar flow conditions. The result? Homogeneous mixtures with consistent quality—without moving components or external power.

Types of Static Mixers and Their Applications

Static mixers come in various designs to match different industrial needs:

- Helical mixers: Ideal for general-purpose blending of fluids with similar viscosities.

- Plate-type mixers: Used in high-viscosity or multiphase flow applications.

- Sulzer SMX and SMR designs: Provide enhanced mixing efficiency and lower pressure drops.

- Static T-mixers: Common in chemical dosing and water treatment systems.

In industries like pharmaceutical manufacturing, they ensure precise ingredient ratios; in wastewater treatment, they help evenly distribute chemicals; and in polymer production, they mix additives into molten plastics for consistent properties.

Advantages of Static Mixers Over Mechanical Mixers

Static mixers offer several benefits that make them an attractive choice for industrial applications:

- No moving parts – minimizing wear and reducing maintenance needs.

- Compact and efficient – requiring less space and energy than traditional mixers.

- Reliable and repeatable results – ensuring process consistency.

- Cost-effective – lower capital and operational expenses over time.

- Versatile – effective for liquids, gases, and even solid-liquid mixtures.

For processes that demand continuous operation and minimal downtime, static mixers often outperform dynamic alternatives.

Materials and Design Considerations

The choice of materials for static mixers depends on the process media and operating conditions. Stainless steel is preferred for high-pressure and high-temperature applications, while PTFE or PVC variants are used for corrosive chemicals. Glass-lined and alloy options also exist for industries requiring extreme chemical resistance.

Design parameters like element geometry, diameter, and number of elements influence the mixing efficiency and pressure drop. Engineers often use Computational Fluid Dynamics (CFD) to model and optimize designs before production—ensuring precise performance.

Static Mixers in Key Industries

Static mixers are integral to a variety of applications across industries:

- Chemical processing: For blending reactants, neutralizing acids, and gas absorption.

- Water and wastewater treatment: To distribute coagulants, pH adjusters, and disinfectants uniformly.

- Food and beverage: For blending ingredients such as flavorings, colorants, and stabilizers.

- Pharmaceuticals: To ensure homogeneity in sensitive liquid formulations.

- Energy and environmental sectors: For gas scrubbing, heat recovery, and emissions control.

These examples highlight their adaptability to nearly any continuous process.

Maintenance and Operational Tips

One of the greatest strengths of static mixers is their low maintenance requirement. However, to maximize performance and longevity, regular inspection is recommended. Checking for fouling, scaling, or blockage ensures smooth flow and consistent output. Cleaning procedures depend on the media—CIP (Clean-in-Place) systems are often used in sanitary applications to avoid disassembly.

Periodic performance reviews also help verify that the mixer continues to deliver the desired blend quality and pressure conditions.

Energy Efficiency and Sustainability Benefits

In a world focused on sustainability, static mixers provide a clear advantage. Since they have no motors or moving parts, they consume virtually no additional energy beyond the system’s natural flow pressure. This not only reduces power consumption but also decreases carbon emissions.

By optimizing chemical reactions and reducing waste, static mixers contribute to both economic and environmental efficiency—aligning with modern process sustainability goals.

Selecting the Right Static Mixer for Your Process

Choosing the right static mixer requires evaluating process parameters such as viscosity, flow rate, temperature, and chemical compatibility. Working with experienced suppliers ensures that the mixer’s design matches the specific application—whether it’s for chemical dosing, heat exchange, or reaction enhancement.

ZAIN Industrial offers a range of static mixing solutions engineered for reliability and precision. To learn more, explore our Static Mixing Equipment page for advanced mixing technologies designed for your industry.

Conclusion: The Power of Passive Mixing

Static mixers represent one of the most elegant solutions in process engineering—blending efficiency, reliability, and sustainability into one compact device. From their origins in the 1960s to today’s advanced designs, they’ve remained a cornerstone of modern fluid processing.

If you’re looking to optimize your mixing performance or learn more about industrial mixing equipment, reach out to ZAIN Industrial today. Our experts can help you select the ideal solution for your process.

Additional Information

For further reading, you may also explore:

These pages provide valuable insights into the principles of mixing and how equipment selection impacts efficiency and product quality.