Common Applications of Glass-Lined Reactors in the Chemical Industry

Introduction: Why Glass-Lined Reactors Matter

In the chemical industry, equipment reliability and product purity are non-negotiable. Glass-lined reactors (GLRs) have become a preferred solution for many manufacturers because they combine the strength of steel with the chemical resistance of glass. This dual benefit makes them versatile and indispensable for processes that demand durability, safety, and consistency.

In this article, we’ll explore the common applications of glass-lined reactors in the chemical industry, their role in supporting complex reactions, and why they continue to be the equipment of choice across diverse sectors.

What Are Glass-Lined Reactors?

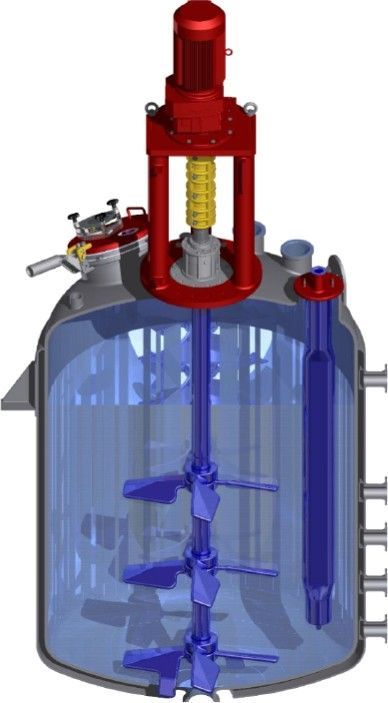

Glass-lined reactors are steel vessels coated with a layer of high-quality glass fused onto the surface. This fusion provides corrosion resistance, chemical inertness, and ease of cleaning—qualities essential for the chemical industry.

They are widely used for processes involving corrosive chemicals, volatile reactions, or products requiring absolute purity. Industries that demand safety and reliability, such as pharmaceuticals, agrochemicals, and specialty chemicals, often choose glass-lined reactors over alternatives like stainless steel.

Application in Acid and Alkali Reactions

One of the most common uses of glass-lined reactors is in acidic and alkaline environments. Many chemicals, such as sulfuric acid, hydrochloric acid, and caustic soda, are highly corrosive to metal surfaces.

With a glass lining, reactors can handle these harsh chemicals without corrosion, ensuring longer equipment life and minimizing contamination risks. This makes them ideal for large-scale neutralization, synthesis, and reaction processes.

Role in Polymerization Processes

Polymer production requires precise reaction control and environments that prevent unwanted contamination. Glass-lined reactors are often used for polymerization because their inert lining ensures that polymers like resins, plastics, and rubbers are not compromised during production.

For example, producing high-purity specialty resins often requires reactors that can withstand both high temperatures and corrosive intermediates—conditions well-suited to glass-lined reactors.

Use in Agrochemical Manufacturing

The agrochemical industry relies heavily on glass-lined reactors for processes involving pesticides, herbicides, and fertilizers. These compounds are not only reactive but also potentially hazardous if handled improperly.

GLRs provide the necessary containment while also ensuring that no cross-contamination occurs, which is critical when producing chemicals used in farming and food-related supply chains.

Pharmaceutical Applications: Ensuring Purity and Safety

Purity is paramount in pharmaceutical manufacturing. Glass-lined reactors are used in the formulation of active pharmaceutical ingredients (APIs) and other drug components because they prevent contamination from metallic ions and ensure product integrity.

Additionally, their easy-to-clean smooth surface allows for faster changeovers between production runs, which is vital in multipurpose pharmaceutical facilities.

Support for Hydrogenation and Other High-Pressure Reactions

Glass-lined reactors are also employed in hydrogenation processes and other reactions that require high pressures and temperatures. Their robust steel shells provide the necessary strength, while the glass lining protects against corrosive catalysts and intermediates.

This combination makes them suitable for producing specialty chemicals, dyes, and other compounds that rely on controlled hydrogenation.

Application in Specialty and Fine Chemicals

The production of fine chemicals—such as fragrances, flavors, and specialty coatings—requires precision and consistency. Because glass-lined reactors prevent contamination and resist chemical attack, they are ideal for such high-value, sensitive processes.

Their versatility also supports multi-step reactions where different reagents and conditions are applied within the same equipment.

Ease of Cleaning and Reduced Downtime

Another major application advantage is found in multi-batch operations. Many chemical plants need to produce different products in the same equipment. Glass-lined reactors, with their smooth, anti-stick surfaces, make cleaning simple and reliable.

This minimizes downtime between batches and ensures compliance with Good Manufacturing Practices (GMP), which are especially important in regulated industries.

Energy Recovery and Heat Transfer Efficiency

Glass-lined reactors are often designed with integrated jackets for heat transfer, allowing efficient heating and cooling of reaction mixtures. This is critical in the chemical industry, where precise temperature control directly impacts reaction yields and safety.

Applications requiring exothermic or endothermic reactions benefit from this efficient energy management.

Choosing Glass-Lined Reactors for Long-Term Value

From durability and safety to versatility and compliance, glass-lined reactors offer a broad range of advantages across the chemical industry. Whether used for acid reactions, pharmaceuticals, or specialty polymers, they deliver consistent performance and long-term value.

For companies weighing reactor options, GLRs often prove to be the smarter investment, thanks to their ability to extend equipment life, minimize maintenance, and ensure product integrity.

Conclusion: Why They Remain a Top Choice

Glass-lined reactors have earned their place as a cornerstone of chemical processing. Their ability to withstand harsh conditions, maintain purity, and adapt to various applications makes them a reliable and cost-effective choice for manufacturers worldwide.

If you’d like to learn more about how glass-lined reactors can improve your processes, reach out to ZAIN Industrial today to get started. At ZAIN, we provide specialized solutions to keep your operations efficient and reliable. For those looking to enhance production, our Glass-Lined Stirred Tanks & Reactors deliver durability, corrosion resistance, and superior product purity. Our Glass Inspection & Repair Services help you identify and resolve damage in glass-lined equipment before it impacts performance, ensuring safety and compliance.