Choosing Between Glass-Lined and Standard Mixing Equipment

Selecting the right mixing equipment is one of the most important technical and financial decisions you’ll make for a process line. The choice between glass-lined and standard (stainless steel / specialty alloy) mixing equipment affects product purity, maintenance, operating cost, regulatory compliance, and long-term reliability. This guide walks you through the practical tradeoffs, real-world scenarios, and a clear decision checklist so you can pick the equipment that best fits your process requirements.

What “Glass-Lined” vs. “Standard” Really Means for Your Process

When we say glass-lined, we mean steel or alloy vessels whose wetted interior is fused with a chemical-resistant glass layer (typically borosilicate). That glass creates an inert, non-reactive barrier between process fluids and the metal substrate. Standard equipment usually refers to stainless steels (304/316L) or specialty alloys chosen for mechanical strength, temperature/pressure capability, and corrosion resistance. The materials behave differently with respect to chemical attack, cleanability, thermal cycling, and physical wear—so the right choice depends on what you mix, how you run it, and how you maintain it.

Performance & Product Quality Considerations

Product purity and contamination risk are often the decisive factors. Glass-lined interiors are essentially inert: they don’t leach metal ions, won’t catalyze side reactions, and minimize adsorption of trace organics—a big advantage for APIs, fine chemicals, and food ingredients. Stainless steel can be perfectly adequate for many chemistries, but it sometimes permits ion transfer or passive film changes under aggressive conditions. If small levels of metal contamination can affect potency, color, or shelf life, glass-lined equipment gives you a much safer margin for product quality.

Corrosion Resistance vs. Mechanical Robustness

Glass lining excels at resisting acids, alkalis, and many organic solvents—but it is brittle compared with metal. If your application uses highly corrosive media that would rapidly attack stainless steel, glass lining often avoids frequent replacement. Conversely, for extremely abrasive slurries, high-impact solids, or very high pressures and temperatures, specialty alloys or lined metallic coatings may be mechanically superior. Think of glass as exceptional chemical armor with mechanical limits; think of alloys as strong structural performers that may require sacrificial maintenance when chemistry is hostile.

Cleaning, CIP/SIP, and Regulatory Compliance

Glass’s smooth, non-porous surface supports robust clean-in-place (CIP) and steam-in-place (SIP) protocols, making it easier to validate cleaning and reduce cross-contamination risk. That’s why glass-lined vessels are common in pharma and high-purity food processing. Stainless steel can also meet CIP/SIP standards, but cleaning regimes and validation steps are often different—you may need harsher chemicals or longer cycles. Evaluate the regulatory demands of your product (cGMP, FDA, food safety) when comparing options—compliance cost can outweigh small differences in CapEx.

Lifecycle Cost: Beyond the Purchase Price

Upfront cost is only the first line in the budget. Glass-lined vessels typically carry higher initial price tags, but they can reduce total cost of ownership when they avoid expensive corrosion damage, product rework, or contamination events. Standard alloy tanks may be less expensive to buy but require more frequent maintenance, passivation, or replacement in corrosive service. Do a simple lifecycle calculation: factor in expected maintenance intervals, downtime cost per hour, expected service life, and potential product loss from contamination. Often the true ROI favors the technology that reduces unplanned outages and scrap.

Maintenance, Inspection and Repairability

Glass linings are inspectable (visual checks, spark/holiday testing, thickness gauges) and repairable either on-site for small defects or via reglassing for larger refurbishment. We offer glass inspection & repair services to help customers extend vessel life without full replacement. Alloy vessels have different maintenance profiles—mechanical repairs are often quicker, but corrosion or pitting can be progressive and harder to fully remediate. Think about your maintenance capabilities and whether you want to invest in reglassing, spare liners, or more frequent process shutdowns.

Operational Constraints and Process Dynamics

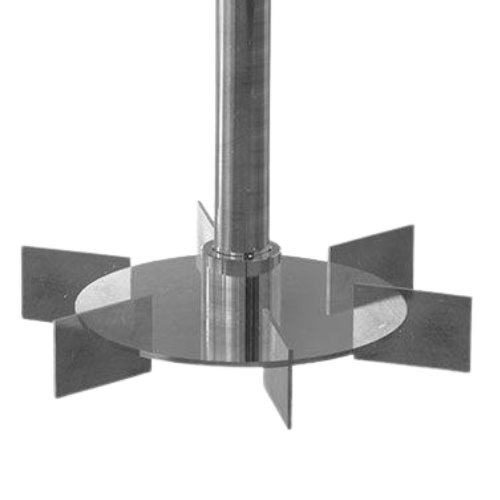

Consider operating temperature, pressure, agitation type, and solids loading. Glass-lined systems are excellent for many temperature ranges and moderate pressures, but there are limits: hydrofluoric acid, certain phosphates, or extreme thermal shock scenarios are poor matches. If your process sees heavy mechanical abrasion, high shear, or very high torque requirements, ensure agitator designs, bearing supports, and shaft seals are compatible with the lining. If you’re unsure about mixing dynamics, a mixing efficiency review can identify whether equipment changes, impeller geometry updates, or process parameter tuning will let you keep existing hardware.

Case Scenarios to Guide Your Decision

- Fine chemical / API synthesis—small tolerances for contamination, frequent cleaning, and corrosive reagents. Recommendation: Glass-lined reactors for inertness and CIP/SIP compatibility.

- Bulk chemical neutralization—large volumes, lower purity needs, solids handling. Recommendation: Alloy tanks (stainless/specialty) with wear-resistant internals.

- Food flavor blending—food-grade, easily cleaned, but typically not extremely corrosive. Recommendation: Stainless steel unless acid concentrations are high; consider glass-lined where flavor contamination is critical.

- Pilot lab-scale R&D—Need rapid iteration and visibility. Recommendation: small glass-lined reactors can aid purity and observation; renting or modular equipment often makes sense.

These scenarios highlight how product risk, operating profile, and production scale shift the balance between glass-lined and standard equipment.

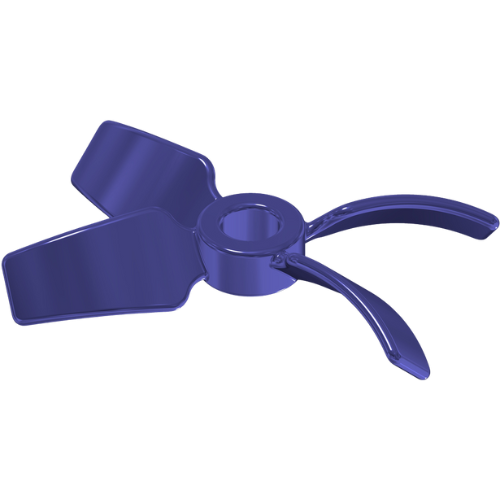

Integration, Spare Parts and Vendor Ecosystem

Standard equipment often benefits from a wide vendor base and interchangeable parts (pumps, seals, and agitators). Glass-lined systems are produced to high standards but require compatible spare parts (glass-lined agitators and gland seals designed for liners). If you prefer to avoid single-source risk, evaluate vendors’ spare part availability and aftermarket support. ZAIN’s impartial consulting helps you compare vendor proposals and technical specs to ensure long-term serviceability and fair pricing—see our product lines for the types of vessels we specialize in supporting.

Making the Decision: A Practical Checklist

Use this checklist to decide objectively:

- Is product purity or metal contamination a showstopper? (If yes → glass-lined)

- Are process fluids known to aggressively corrode stainless alloys? (If yes → glass-lined)

- Will the service see heavy mechanical abrasion or extreme pressure? (If yes → alloy or specialized coating)

- How important are CIP/SIP and cleanroom compliance? (If high → glass-lined)

- What is acceptable downtime, and what is the cost per hour of downtime? (Higher cost → prefer longer life solution)

- Do you have access to reglassing/inspection services? (If not, account for logistics.)

If in doubt, run a short mixing audit—our Mixing Efficiency Review can quantify how equipment changes would impact energy, cycle time, and blend quality before you commit.

Implementing Your Choice and De-Risking the Project

Once you’ve chosen, reduce risk by specifying clear RFQs (lining thickness, finish, jacket design), planning for inspection intervals, buying critical spares (seals, bearings), and establishing a maintenance contract. If choosing glass-lined equipment, include inspection and repair clauses; if choosing standard alloys, include corrosion monitoring protocols. ZAIN can help prepare RFQs, evaluate bids, and set up inspection schedules so your capital purchase becomes a stable production asset rather than a liability.

Conclusion

Choosing between glass-lined and standard mixing equipment is not a binary “better/worse” question—it’s a tradeoff exercise driven by chemistry, product risk, operational profile, and lifecycle economics. Glass-lined equipment delivers superior chemical inertness and cleaning performance for purity-critical or highly corrosive processes, while standard alloys offer mechanical strength and broad applicability at lower CapEx. Evaluate your process against the checklist above, run targeted mixing and inspection audits where needed, and build a maintenance plan that matches your choice. If you’d like help matching equipment to your process, preparing RFQs, or running an efficiency/audit program, reach out to discuss how we can help you get it right.